Create Precise Production Strategy and Material Requirements

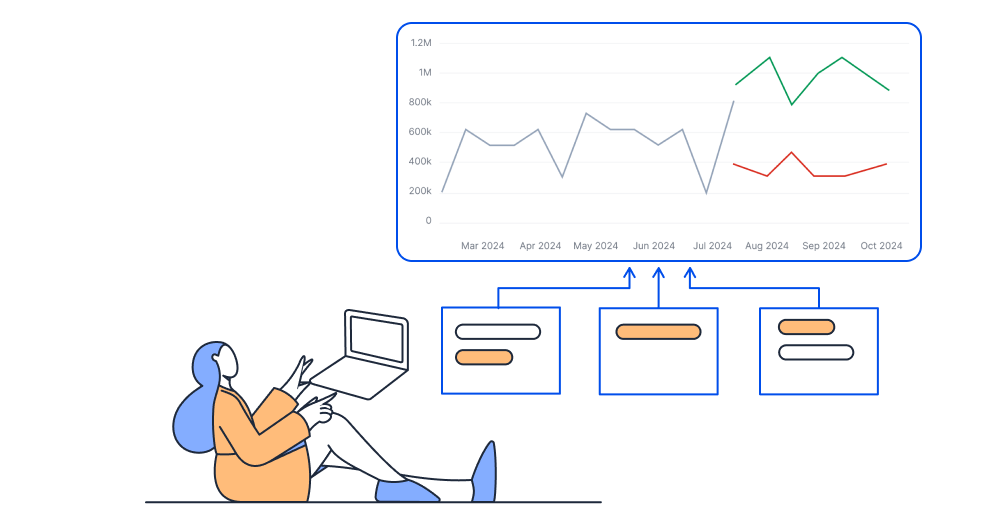

Streamline offers a comprehensive solution that integrates demand forecasts with your Bill of Materials (BoM) to generate detailed production plans and material requirements. The platform calculates a detailed material requirements plan, which can be dynamically adjusted to accommodate changes in demand and supply chain disruptions, ensuring agile operations.

Ensuring Timely Availability

By accurately predicting demand, Streamline helps ensure that materials are available exactly when needed. This reduces lead times and prevents delays in the production process, enabling you to meet customer orders on time and improve overall satisfaction.

Maximizing Productivity

By having the right materials at the right time, Streamline helps you avoid production halts and ensure a smooth workflow. This not only maximizes productivity but also enhances operational efficiency, allowing you to achieve higher output with the same resources.

Reducing Waste and Enhancing Efficiency

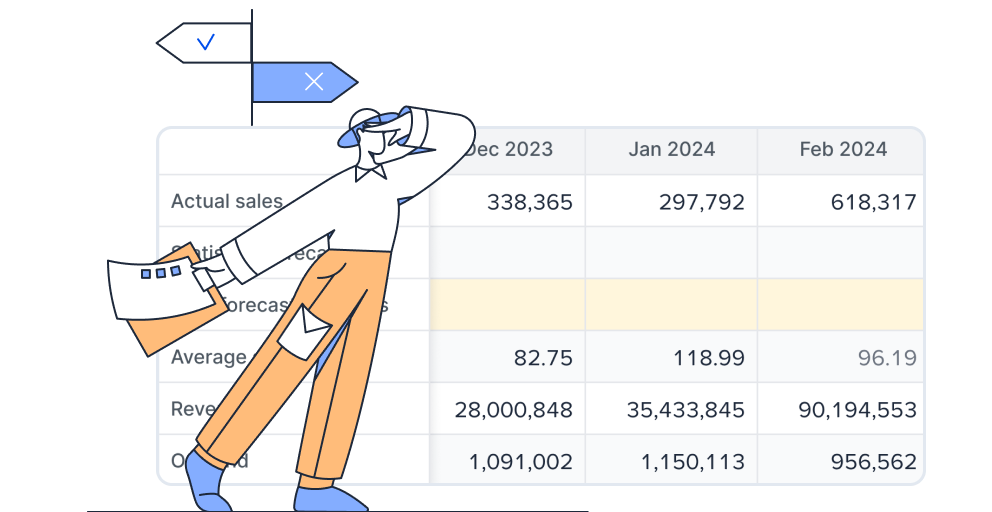

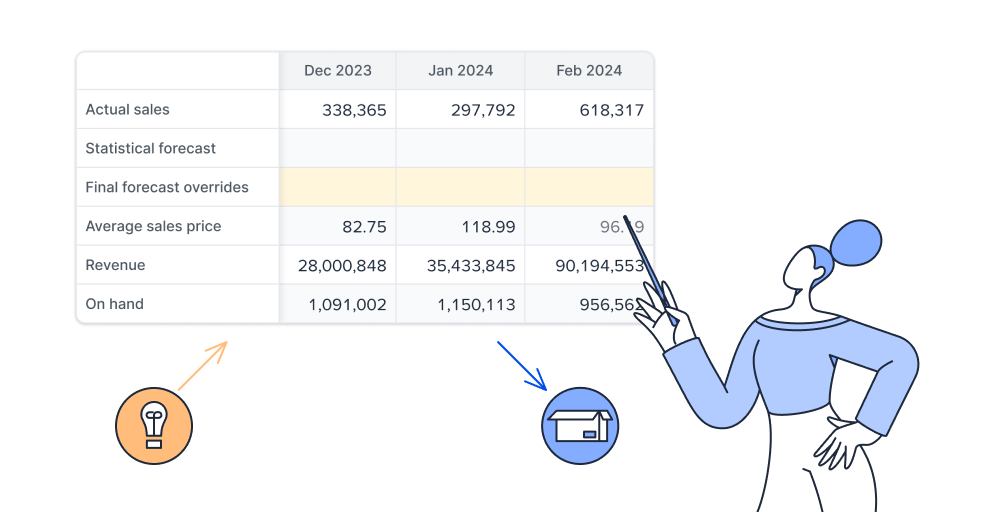

Accurate reporting and easy data export help reduce material waste and improve overall efficiency. By having a clear view of your inventory and production needs, you can minimize surplus stock and ensure that resources are used optimally.

Automation: The Key to Overcome the Challenges of Manual Production

Discover how Streamline AI can transform your material requirements planning process, drive efficiency, and streamline your supply chain operations.

Reduce Risk of Material Stockout for Production

With Streamline’s automated material requirements planning, you can reduce the risk of material stockout for production. Our platform takes into account the latest demand forecasts and BoM information, supporting multi-level BoM, and ensuring that you always have the right materials available when you need them. This helps to reduce the risk of production delays due to any unexpected stockout.

Production Line Planning

Streamline helps to organize and optimize the workflow and resource allocation in manufacturing to ensure efficient production, meet demand, and minimize costs and delays.

Batch Production Planning

Batch Production Planning or recipe management is crucial when specific formulations and precise processes are required for different products. Using Streamline, manufacturers ensure that each product batch is produced consistently and efficiently, adhering to the necessary quality standards and regulatory requirements.

Distributed Manufacturing Planning

Easily plan manufacturing in different locations involves leveraging advanced production line planning and capacity planning tools to coordinate and optimize workflows, resource allocation, and production schedules across multiple facilities.

Inventory optimization for a 30 years old catering manufacturer

How Streamline overcame stock-outs by implementing demand planning and forecasting, resulting in a 30% decrease in excess stock for a catering manufacturer.

Read full story