The first five steps of Supply Chain Officer in a New Position

Get the Guide to Navigate Your First Steps as a Supply Chain Officer

The challenge

Starting the role of Supply Chain Director presents a unique set of challenges. We frequently receive demo requests from people who have assumed this position within the last six months, navigating a particularly demanding scenario.

These professionals find themselves in a challenging predicament, as the company not only anticipates results from them but also expects solutions to existing problems. Compounding this, the team has had insufficient time to establish a relationship with the new Supply Chain Director and, consequently, resists the changes mandated by the role. This resistance is deeply rooted in the team’s powerful habits, making any proposed changes a formidable undertaking.

The solution

Playing the role of a ‘wind of change’ or a doctor administering necessary pain for long-term improvement is indeed a daunting task. At GMDH Streamline, we’ve curated valuable suggestions to help navigate and overcome these challenges.

The first 5 steps to set you on the path to success:

Evaluate the Current State of the Company.

Set up SMART Goals.

Find a Tailored Solution.

Book Demos and Prove Value.

Plan for the Future.

Evaluate the Current State of the Company

Assess the strengths, weaknesses, and areas needing improvement. Dive into historical data, especially if Excel has been the primary planning tool. Identify previous shortcomings and calculate key performance indicators (KPIs).

Set up SMART Goals

Once problems are identified, establish Specific, Measurable, Achievable, Relevant, and Time-bound (SMART) goals.

Specific

Firstly, ensure that your goals are Specific, leaving no room for ambiguity. Clearly articulate the desired outcomes, such as enhancing forecasting accuracy or optimising inventory levels.

Measurable

Next, make sure your goals are Measurable. Establish metrics and key performance indicators (KPIs) that allow you to quantify progress.

Achievability

Achievability is a critical aspect to consider. While it’s essential to aim high, goals should be realistically attainable.

Relevance

Relevance is another key factor in goal-setting. Align your goals with the overarching objectives of the company and the challenges identified in the initial assessment.

Time-bound

Lastly, imbue your goals with a Time-bound element. Define a clear timeframe within which these objectives should be accomplished.

Find a Tailored Solution

Seek a solution that aligns with your processes, optimises them, and can achieve your goals. It is better to consider solutions implemented by experienced consultants who understand your company’s processes and can map them with the chosen solution. Additionally, consider the reputation of potential solutions on reputable platforms like G2.com and Gartner, where recognition and positive reviews underscore their reliability and effectiveness in addressing diverse supply chain challenges.

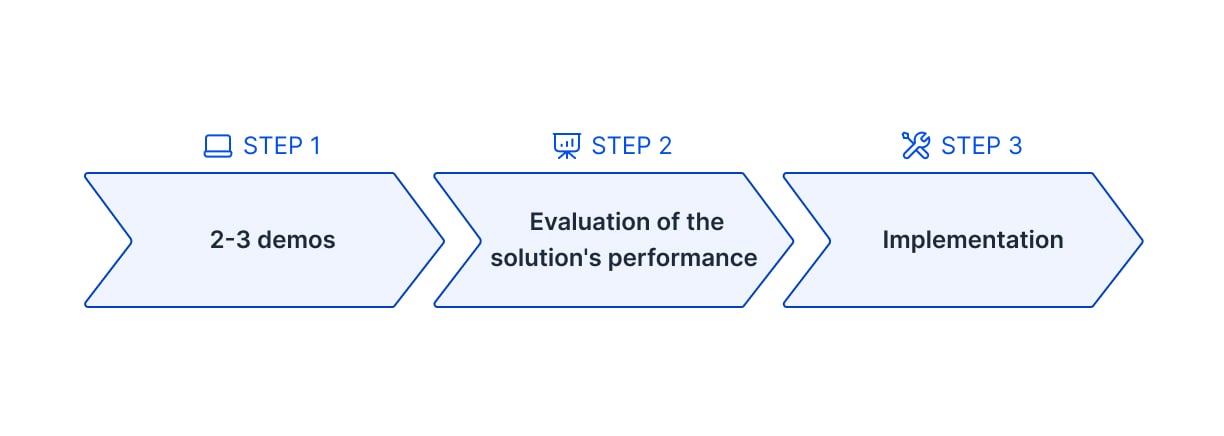

Book Demos and Prove Value

Schedule 2-3 demos with top-listed solutions. After demos, it’s crucial to prove the value. It’s imperative to go beyond surface-level presentations and request a test project utilising your own data. This step allows for a hands-on evaluation of the solution’s performance by comparing its forecast against actual data and benchmarking it against your team’s demand forecast. Only after thorough evaluation and confirmation that the solution not only outperforms but also aligns seamlessly with your goals should you confidently proceed toward implementation.

Plan for the Future

Look ahead to anticipate the company’s future needs. Consider the scalability of planning tools, even if sophisticated features may not be necessary at present. As your team gains experience and the company expands, there will be evolving requirements that the chosen solution must accommodate.

Develop a roadmap

Develop a roadmap for integrating workflow systems, addressing inventory reporting challenges, and enhancing planning tools.

Prepare your team for implementation

Clearly outline responsibilities in the implementation agreement, select a project manager and IT specialists, that have the capacity for the project and will not put the project back.

Safeguarding success

Clarify Implementation Acceptance Criteria and prioritize consultant support during the first order cycle.

Streamline the process

Being a ‘wind of change’ is challenging, but change is necessary for achieving new and improved results. At Streamline, we offer unwavering support, deep involvement in your company’s processes, and mapping them with our solution to meet business challenges and boost profitability. With Streamline, it’s not just about adapting to change; it’s about leveraging it to catalyze positive, sustainable, and profitable transformations within your organization.

Trusted by industry leaders worldwide

Our platform enables thousands of companies to optimize their supply and demand planning. They root for us, and they aren’t shy about it.

Streamline is the best choice on the market to manage and optimize stock levels. This software is the easiest way to start the demand planning and inventory optimization journey because it’s easy to implement.

“The best platform to forecast demand and supply! GMDH provide tools to control our product and inventory stock-up management. The program will calculate based on the current demand, manufacturing cost and warehouse space to make our business is effective in inventory control and supply management.”

“Supply chain problems, try this platform you won't regret it. This tool has become my right-hand companion, Its like having an extra pair of hands!”

“Streamline provides our company with a streamlined approach to inventory management and forecasting. Its user-friendly interface reduces manual workload, leading to more accurate and time-efficient planning. This tool has significantly enhanced our supply chain operations. Review collected by and hosted on G2.com.”

“Streamline has been very helpful in reducing the time and effort required to calculate our purchasing requirements and placing our purchase orders. Previously we used complex spreadsheets which were quite cumbersome but Streamline has made the process at least 100% faster. After using it for more than 1 year, it has also resulted in a 5-10% reduction in stockholding with minimal impact on fill rate.”

“We were like firefighters, not supply chain managers. We saw the results in the first month after Streamline implementation. A 90% time spend on daily routine was reduced and inventory had dropped by 36% with Streamline. The company has been able to eliminate two auxiliary buildings rented month-to-month. That has saved about $56,000/month in excess storage costs for them.”

“Streamline has an excellent set of features that are easy to use and implement. With their incredibly responsive team, Streamline is an outstanding choice.”

“Advance Supply Planning System Which Is User Friendly. The ease of use along with advanced features is something that makes Streamline a quick starter system. We have been associated with Streamline for a few years and have constantly seen enhancements to its capabilities based on the user`s feedback.”

“Customer service is patient, responsive and very helpful. The program has helped us tremendously as we grow our inventory and SKU count.”

“Streamline is a game-changer when it comes to data analysis and predictive modeling. As an avid data scientist, I have tried numerous software tools and algorithms, but none have impressed me as much as GMDH S.T. Streamline. This software stands out with its streamlined user interface, robust feature selection, and impressive accuracy in forecasting.”

“I am very impressed with how well GMDH Streamline can predict future sales. This intelligent software uses advanced mathematical algorithms to accurately determine the ideal stock levels for our business operations. By utilizing this powerful tool, we can make sure that we maintain optimal inventory levels, avoiding both excess and shortage issues. Review collected by and hosted on G2.com.”